Round Bottle 220V 50HZ Filling Capping Labeling Machine For Industrial

Product Details:

| Place of Origin: | GUANGHZOU |

| Brand Name: | Weidong |

| Certification: | CE |

| Model Number: | WD-LBM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | negotiable |

| Packaging Details: | wooden case |

| Delivery Time: | 15 Work days |

| Payment Terms: | TT |

| Supply Ability: | 30set per month |

|

Detail Information |

|||

| Dimension: | Customized | Name: | Labeling Machine |

|---|---|---|---|

| Control System: | PLC | Labeling Accuracy: | High |

| Operation Mode: | Semi-Automatic | Weight: | 45KG |

| Capacity: | High | Warranty: | 1 Year |

| Highlight: | Round Bottle Filling Capping Labeling Machine,Industrial Filling Capping Labeling Machine |

||

Product Description

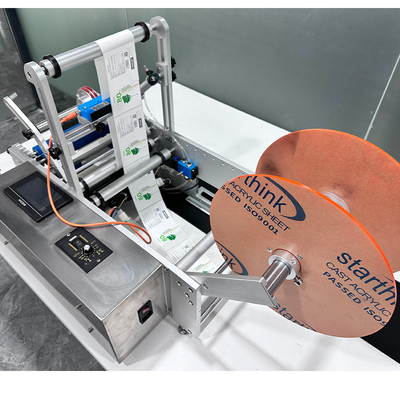

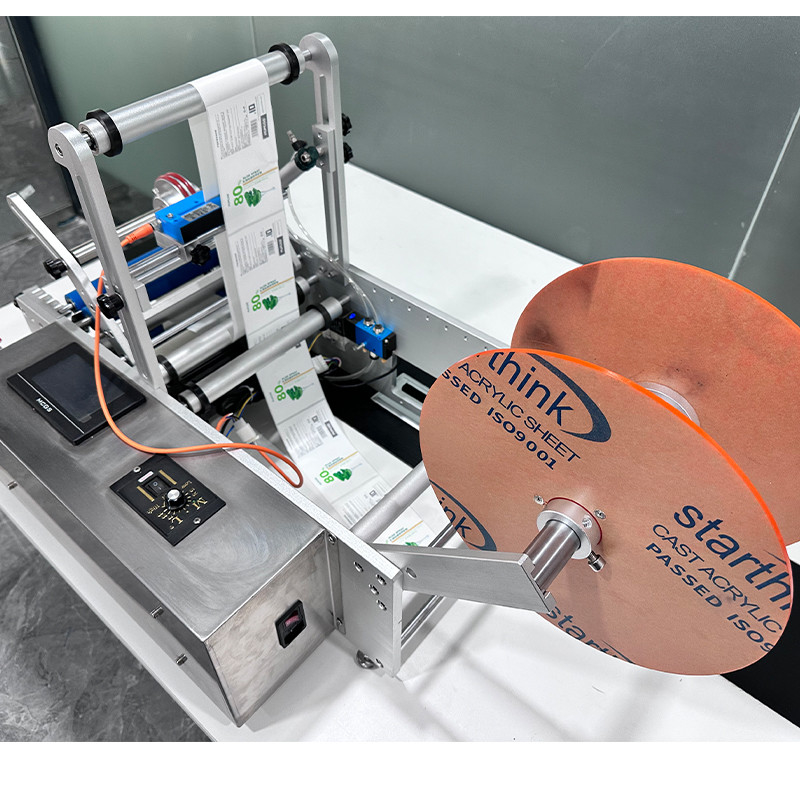

Semi-Automatic 220V/50HZ Labeling Machine for Industrial Use

Product Description:

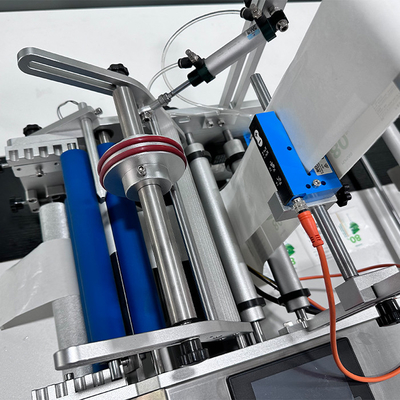

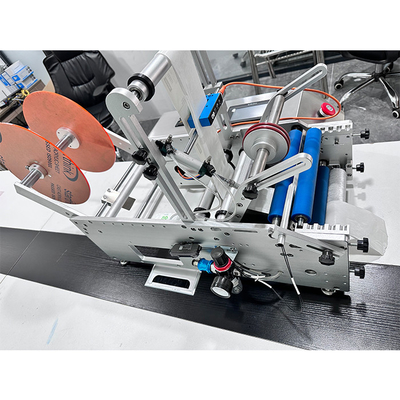

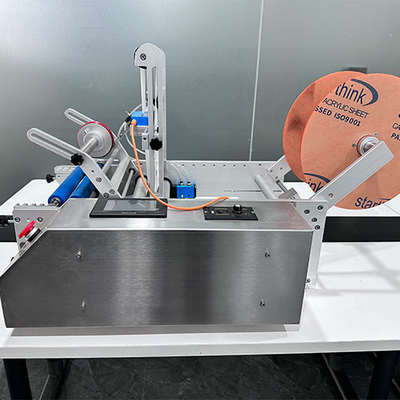

Semi-automatic round bottle labeling machine is mainly used in medicine, daily chemical industry, food and other cylindrical bottle surface semi-automatic labeling. It adopts high-precision labeling device, which can adapt to a variety of different size range of product labeling. Compared with manually labeling, it can save manpower effectively, and improve labeling accuracy and consistency. It is of light structure, with high strength and corrosion resistance, and meets GMP standards. Using imported electric eye and program controller to control synchronous motor labeling, you can paste 1 or 2 labels on a bottle. The parts exposed strength are used ss engineering plastics, high-strength alloy aluminum with anodized surface treatment. The semi-automatic round bottle labeling machine is a kind of machine that great for those who need accurate labeling. Not only the accuracy improved but also the labeling speed, producing more labels with fewer labor. The exposed parts of the machine are made with high-quality material which could increase the durability and reduce the risk of rust. Practically, this machine can cut the cost of manpower and increase the efficiency of product labeling.Applications:

Labeling technology is widely used in many industries with its various applicable labels, such as self-adhesive label, non-adhesive film, electronic supervision code, bar code, etc.It is applicable for products that requre labels on its circumferential and conical surfaces, such as oral liquid round bottle, celine bottle, xylitol bottle and etc. It is widely used in industries like food, medicine, daily chemical, electronics, hardware, plastic and etc. Moreover, this labeling process can be used for products of different shape such as shampoo bottle, small taper cosmetic bottle and etc.

Customization:

Brand Name: Weidong

Model Number: WD-LBM

Place of Origin: GUANGHZOU

Certification: CE

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: Wooden Case

Delivery Time: 15 Work Days

Payment Terms: TT

Supply Ability: 30set per Month

Material: Stainless Steel

Operation Mode: Semi-Automatic

Type: Semi-Automatic

Weight: 45KG

Filling Accuracy: High

Weidong WD-LBM Filling Capping Labelling Machine is a high-precision labelling machine. It is made of stainless steel for durability and reliability. This labelling machine is semi-automatic, and is suitable for a wide range of products. It is easy to operate and comes with a minimum order quantity of 1. It delivers within 15 working days and can be shipped in a wooden case. The price is negotiable and the payment terms are TT. Weidong guarantees excellent filling accuracy and a supply ability of 30sets per month.

Support and Services:

Labeling Machine Technical Support & Service

We provide comprehensive technical support and services for Filling Capping Labeling Machine. Our experienced technicians can help you with any technical issue you might have. We offer the following services:

- Installation Help – Our technicians will help with the installation of your Filling Capping Labeling Machine, and provide assistance with set up and operation.

- Technical Support – Our team of technical experts can answer any questions you may have and provide advice and assistance on troubleshooting.

- Preventive Maintenance – Our technicians will perform routine maintenance on your Filling Capping Labeling Machine to keep it running smoothly.

- Repairs – Our technicians can diagnose and repair any technical issues you may have with your Filling Capping Labeling Machine.

- Parts and Accessories – We offer a wide selection of parts and accessories for your Filling Capping Labeling Machine.

If you need assistance with your Filling Capping Labeling Machine, please contact our technical support team. We are here to help!

FAQ:

1. Why choose us?

1.1- We have over 20 years experience on machinery making .

1.2- Our factory is located in Guangzhou and another one is in Jiangsu province,more than 100 workers in our factory.

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit our factory!

2,I'm new in our industry, but I'm planing to set up a factory, what can I do ?

We will design the most suitable proposal based on your actual situation, such as the daily production, raw material formula, factory layout, etc. Also we would like to introduce some excellent suppliers of raw materials, bottles, labels, etc if needed. After sales,engineer will be send to fields installation , training and commissioning

3.Can you customize machine ?

As a professional machinery manufacturer for more than 20 years,we have skilled OEM technique.

4. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines. When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call. Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video or pictures. If the problem out of your control, we will arrange engineer to your factory.

5.How about warranty and spare parts?

We provide 1.5 year warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that over than 1.5 year warranty.

6. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

7. What about the delivery time?

In stock machine:1-7days Usually 7-60 Working days(depened on products).